የኢሜል ቅርጸት ስህተት

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

ዜና

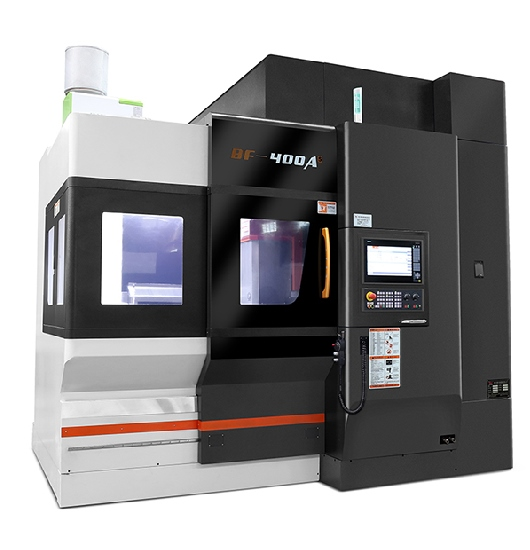

How does 5 Axis CNC Machining Technology Change Automobile and Aviation Manufacturing?

CNC machine tools have incomparable characteristics in the processing process, such as greatly improving productivity, higher machining accuracy, and automation. With the rapid development of automotive, aerospace, aerospace, national defense, and other industries, as well as the application of new materials such as aluminum alloy, the requirements for CNC machine tools are becoming higher and higher. At present, the development of CNC machine tools is changing with each passing day. High speed, high precision, compounding, and intellectualization have become the trend and direction of the development of CNC machine tools.

As a large manufacturing country, there is still a certain gap between China's CNC industry and developed countries. As popular equipment in developed countries, five-axis CNC machine tools with high speed, high precision, and high surface quality are developing rapidly in the Chinese market in recent years.

With the development of five-axis CNC machining technology, its processing quality, efficiency and stability can fully meet the requirements of product production.

Its processed products are also widely used in rail transit, aerospace, automotive, mold, wind power, new energy, new materials, and other industries, of which automotive and aerospace are important sectors.

How can the products made by five-axis linkage machine tools be widely used in the automotive and aviation fields? Let's learn together!

Automobile

Mold part

Many sheet metal parts of automobile bodies need stamping dies, and due to the need for fitting and splicing of accessories, they require high precision. In traditional mold processing, a three-axis machining center is widely used to complete the milling of the workpiece. Upgrading to five axes, on the one hand, can reduce costs, on the other hand, can improve machining accuracy.

Five-axis is the choice to reduce costs

- One-time clamping, multi-faceted processing: there will be no interference during processing. One-time clamping can not only complete the processing but also avoid the repeated positioning error caused by multiple clamping. It not only shortens the time but also saves the large cost of tooling and fixtures when installing the workpiece.

- Reduce equipment investment cost: reduce the floor space and the number of workshops. A five-axis machine has various processes such as turning, milling, drilling, grinding, etc. Engineering intensive production only needs the initial waiting time for debugging, and only needs to import the blank data to complete the programming, which can also greatly shorten the initial preparation.

Five-axis machining accuracy is higher

- Processing of deep cavity mold

When machining deep cavities, the three-axis machining center must lengthen the tool handle and tool, but the five-axis machining center can appropriately shorten the length of the tool through the additional rotation and swing of the workpiece or spindle head, to prevent the collision between the tool and the toolbar and the cavity wall, reduce the vibration and damage of the tool during machining, prolong the service life of the tool, and greatly improve the surface quality and machining efficiency of the mold.

- Processing of mold side wall

When machining the side wall, the length of the tool of the three-axis machining center is larger than the depth of the side wall, and the strength will be significantly reduced by increasing the length of the tool. If the length of the tool is higher than 3 times the diameter, it will be difficult to guarantee the quality caused by the phenomenon of making the tool. The five-axis machining center can make use of the swing of the spindle or workpiece to make the tool and the side wall of the mold always present a vertical state, improve the quality of the workpiece and extend the service life of the tool.

- Machining of the flat surface of the die

When machining flat surfaces, the three-axis machining center needs ball cutter fine milling to increase the tool path, but the linear speed of the center rotation of the ball head cutter tool is almost zero, which will cause great damage to the tool during mold processing, and the service life will decline sharply, and the surface quality will also deteriorate. The application of a five-axis machining center can be processed at a certain angle. Increasing the relative linear speed will not only improve the service life of the tool but also greatly improve the surface quality of the workpiece.

Car body

Lightweight has become the trend of world automobile development. The density of aluminum is about 1/3 of that of steel. Making cars with aluminum instead of steel can reduce the weight of the whole car by 30% - 40%. The light body can greatly improve the speed and handling ability of the car. High-strength aluminum alloy can also bring higher safety performance.

Engine part

The automobile engine is the device that provides power for the automobile and the heart of the automobile, which determines the power, economy, stability, and environmental protection of the automobile.

Take the engine impeller as an example. It is the core component of the suffix "t" of automobile displacement. Its function is to rotate at high speed, inject air into the engine cylinder and pressurize it so that the engine can generate more power.

Engine impeller

The cylinder block is the shell and assembly foundation of the engine. It is generally made of high-quality alloy cast iron or aluminum alloy. The cylinder wall should have effective high machining accuracy and low surface roughness.

Aviation

In the field of aerospace processing, from large-size aircraft shells to the core high-strength engine casings, five-axis processing is indispensable.

Fuselage and wing

The body structure is usually composed of girders, purlins, spacer frames, and skins, which are large, especially the skins that have radians.

Internal structure

A lot of tapping, boring, milling, and other processes are required for the structures inside the aircraft, such as aviation seats, luggage racks, and so on.

Engine case

The engine case is usually made of raw materials that are difficult to process, such as titanium alloy and superalloy. When milling the shape of the engine case, unstable parts, long machining cycles, and difficult machining materials are all challenges.

Searching for a cnc lathe machine 5 axis, 5 axis cnc turning machine, bacci 5 axis cnc supplier, wholesaler, manufacturer from China, you can get high-quality products at a nice price.